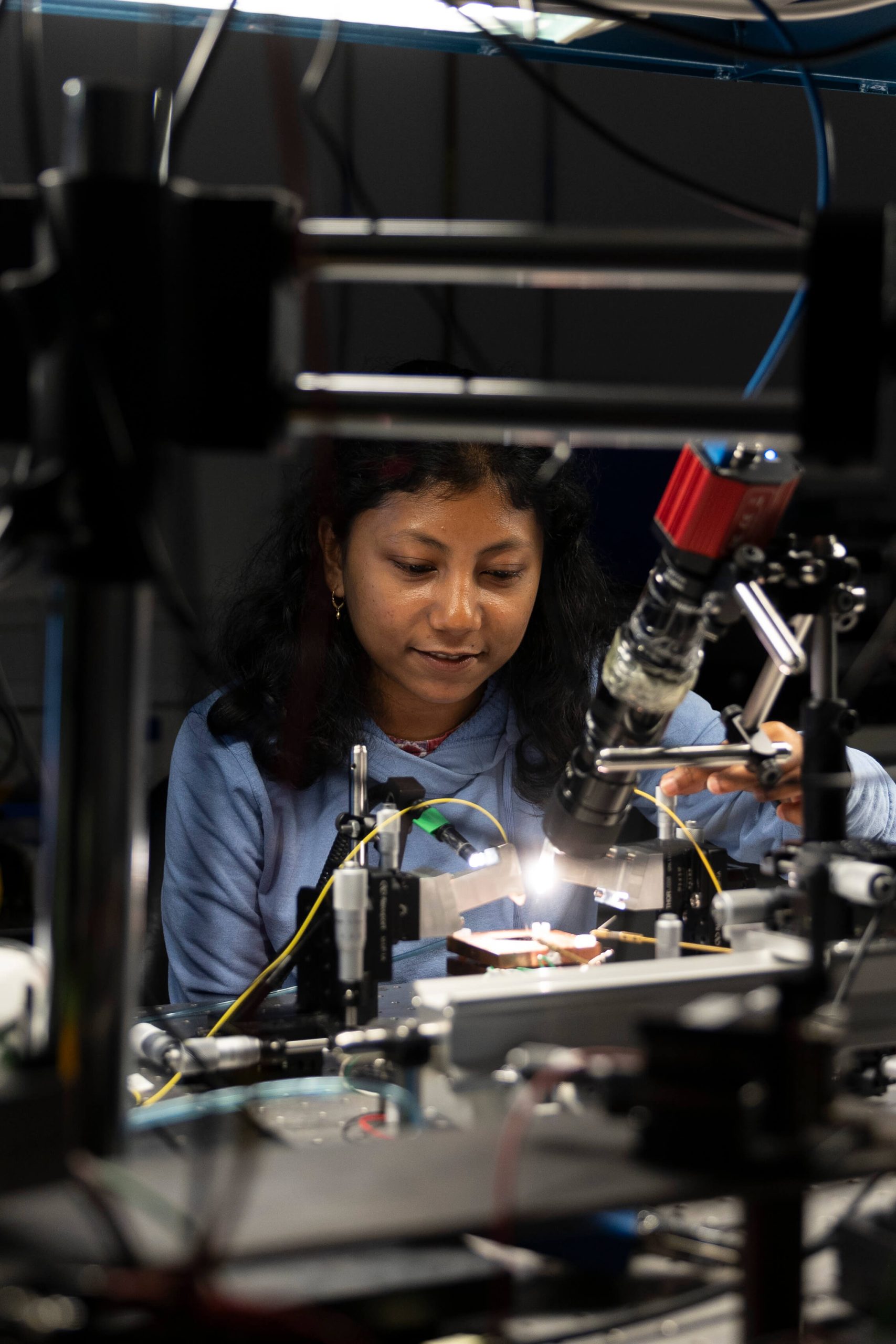

Monolithic and heterogeneous integration

The Monolithic and Heterogeneous Integration research team in photonics are designing, growing fabricating photonic devices and integrating them on chip with silicon photonic circuits.

The outputs from the semiconductor industry are integral to our daily lives and have a vital role to play in addressing many of the critical challenges facing the world today. Our vision is to integrate the best materials and devices in unique and clever ways which will provide many of the required solutions.

Semiconductor photonic devices have now matured to the extent that current research is being driven towards Photonic Integrated Circuits (PICs). This opens up exciting new opportunities to allow photonics to address applications in communications, sensing, AR/VR and artificial intelligence. These PICs are being built on selected waveguiding platforms using a material such as InP, Si or SiN. Monolithic integration on InP provides highly functional circuits meeting the challenge of technological complexity while Si and SiN are compatible with the 300mm wafer size used in state-of-the-art electronic foundries, but lack many essential functional devices such as lasers.

Our mission is to develop leading-edge PICs supporting practical applications while training students and postdoctoral researchers to transition to rewarding careers in industry and academia.

Research Challenge

The challenges are in designing the circuits to take advantage of the wide functionality available and in assembling multiple materials and devices on a common platform while attaining single-mode optical interconnections. There is a particular need to integrate active components (e.g. lasers) on Si and SiN platforms.

Research Focus

Our defining capability is in high-performance active photonic materials and devices based on III-V (InP, GaAs, GaN) and related materials and the integration of those devices into PICs. Using our advanced epitaxial and fabrication technologies we can cover the spectrum from ultraviolet to short-wave infrared.

As examples, we have developed site-controlled quantum (single/entangled) light sources emitting in the 850nm range and coupled the photons to SiN waveguides for further manipulation. We are studying boron-containing nitride materials for next-generation ultraviolet light sources.

We have built multi-wavelength coherent (comb) sources with an integrated locking laser suitable for high spectral density optical communications. We are designing and fabricating prototype Si and SiN waveguiding circuits using our capability in electron beam lithography, which are extensively characterised to select the best circuits for transfer to foundries.

We are heterogeneously integrating our photonic devices with the circuits using transfer printing, a technology we have pioneered. It permits the best materials and devices to be intimately integrated with the waveguide circuits in a scalable manner.

We have deep expertise in the transfer and integration of designed LEDs, lasers, detectors and modulators, and even circuits.

Our current and future research is addressing ever higher performance and functionality. New materials with piezoelectric and magnetic properties are being explored. This comes at the cost of increasing complexity in terms of design and technology.

Our vertically integrated research encompasses many individual research groups addressing fundamental material design, epitaxial growth, active and passive device design and fabrication, integration technology, characterisation, packaging and applications.

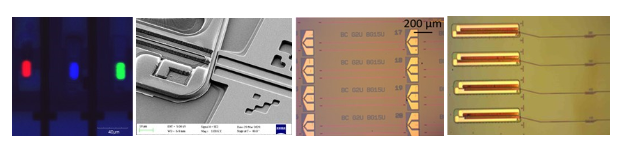

Images show various example of the transfer-print integration of photonic devices.

(a) Red, green and blue LEDs

(b) Detail of laser coupled to Si waveguide

(c) Array of high bandwidth photodiodes integrated to Si waveguides

(d) Array of lasers coupled to external SiN cavities

Recent Publications

H. Muthuganesan, E. Mura, S. Shura, C. Antony, E. Pelucchi, P. Townsend, X. Yan, M. Banaker, Y. Tran, C. Littlejohns and B. Corbett,

“100 Gbps PAM4 ultra-thin photodetectors integrated on SOI platform by micro transfer printing”, Optical Express, 31, 36273–36280 (2023).